Injection Moulding Machine BOY XS V

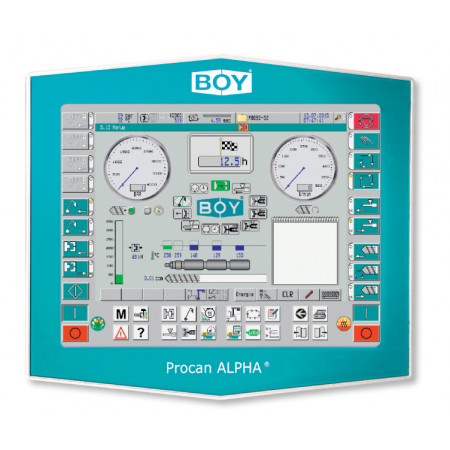

Injection machine BOY XS V with maximal clamping force 100 kN for VERTICAL micro injection moulding from BOY house - injection machine with modern machinery technology with proven technics and all advantages of our bigger machines. This machine is equipped with multi-patented control system Procan ALPHA®4 as well as bigger injection machines.

Clamping Force

100 kN

Screw Diameter

8 mm, 12 mm, 14 mm, 16 mm, 18 mm

Max. Shot Weight

10.2 cm3

Distance between Tie Bars

160 mm (205 mm diagonally)

Processed Materials

thermoplastic, elastomer, silicone (LSR), high wear thermoplastic

Drive

axial piston pump

Producer

Thank you for your inquiry

We will turn back to you as soon as possible with regard to eventual adding of the information or sending of the offer.

Your contact person

Ing. Petr Betáš

Material Dosing and Mixing

Material Dosing and Mixing Products Handling and Automation

Products Handling and Automation