-

PUR Metering Systems KraussMaffei Comet

Metering system Comet is a suitable solution for metering and mixing of PUR materials with abrasive fillers.

-

PUR Low-pressure Metering Machine KraussMaffei

PUR low pressure metering machines are suitable above all for special and highly viscous PUR materials. Very quick exchange of the colours and syst...

-

PUR High-pressure Metering Machine KraussMaffei

PUR high-pressure metering machines belong to the best-sellers from this KraussMaffei category.

-

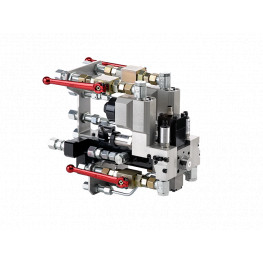

PUR Mixing Heads KraussMaffei

Mixing heads for high-pressure moulding of PUR systems from company KraussMaffei are among top products on the market. KraussMaffei offers ca. 100 ...

-

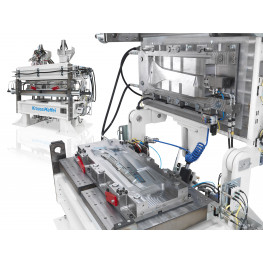

Foaming Moulds KraussMaffei for PUR Technologies

KraussMaffei offers in its complex technology base also moulds and mould carriers (presses). KraussMaffei focuses on moulds for pultrusion technolo...

-

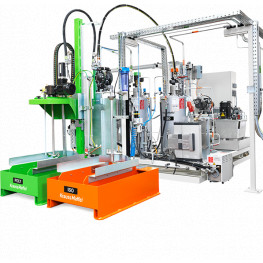

Complete Lines KraussMaffei for PUR Systems

KraussMaffei is perceived as a company offering customers complete solutions for the production of PUR parts and processing of reaction liquids, ep...

-

Post-mould Processing Machines KraussMaffei

Post-mould processing machines KraussMaffei are used mainly in automotive when the moulded part needs to be finalized. KraussMaffei offers these po...

-

Pultrusion Lines KraussMaffei

Pultrusion lines KraussMaffei are used for the production of profiles, tapes and rebar - reinforcement for concrete. Pultrusion lines use new tech...

Material Dosing and Mixing

Material Dosing and Mixing Products Handling and Automation

Products Handling and Automation